Due to retractable awnings’ versatility and improved functionality, many businesses and homeowners choose them over traditional fixed (permanent) awnings. People unfamiliar with the term retractable awnings sometimes refer to them as roll-out awnings or movable awnings, but they all mean the same thing.

The term retractable refers to all adjustable awnings that you can roll out (extend) when the sun is intense or for use with light rain during the day or roll in (retract) in the evening when you want to enjoy the night sky and stars.

Buying an awning is an excellent investment for your backyard, patio or business outdoor area. You can easily create a shady and private relaxation area or entertainment zone without building a permanent structure, but are retractable awnings worth it, and how do they work?

How do retractable awnings work?

You can use a retractable awning to cover driveways, patios, backyards, decks, windows, hot tubs etc. Its mechanism allows you to extend and retract the fabric when you wish, and it serves to create shade on hot and sunny days or protect you from light rain and drizzle.

The retractable mechanism is a fantastic opportunity to extend the awning’s life by retracting it back into its hood/cover or cassette when snow begins to fall, or heavy rain or storm approaches. Extendable awnings also protect people from harmful UV rays and furniture fading and can add privacy to the outdoor area.

What are the parts of a retractable awning?

Retractable outdoor awnings consist of nine primary components. These components may differ depending on the awning model and the manufacturer, and I will discuss each in detail below.

They are :

- A fabric cover or canopy

- A roller tube

- Hood/cover and frame

- Retractable arms

- A front (header) bar

- Cables, chains or belts

- Springs

- Mounting brackets

- A motor or a detachable hand crank

Top picks for retractable awning fabric

The cover or canopy is made of a fabric material that’s an essential component of retractable deck awnings. The fabric provides shade, protects from light rain, and creates an enjoyable outdoor living environment.

Types of fabrics and their features

Vendors choose different fabric brands to work with, but it’s common to offer canvas, duck, polyester, acrylic, solution-dyed acrylic or PVC canopies. However, keep in mind that the cheapest retractable exterior awnings are made from low-quality materials. The cover fades, mildews, rots or tears sooner than later, and the overall awning life will be significantly shorter.

What is the best option?

The top pick and best fabric for rolling awnings are solution-dyed acrylics. Such quality material is offered by major European fabric brands such as Para, Dickson and Recasens and US fabric brand Sunbrella. It is a low-maintenance option that requires minimal effort to maintain, its colors will last for decades, and it’s resistant to rotting, mold, mildew, fading and wear and tear.

What are retractable awning roller tubes and cassettes?

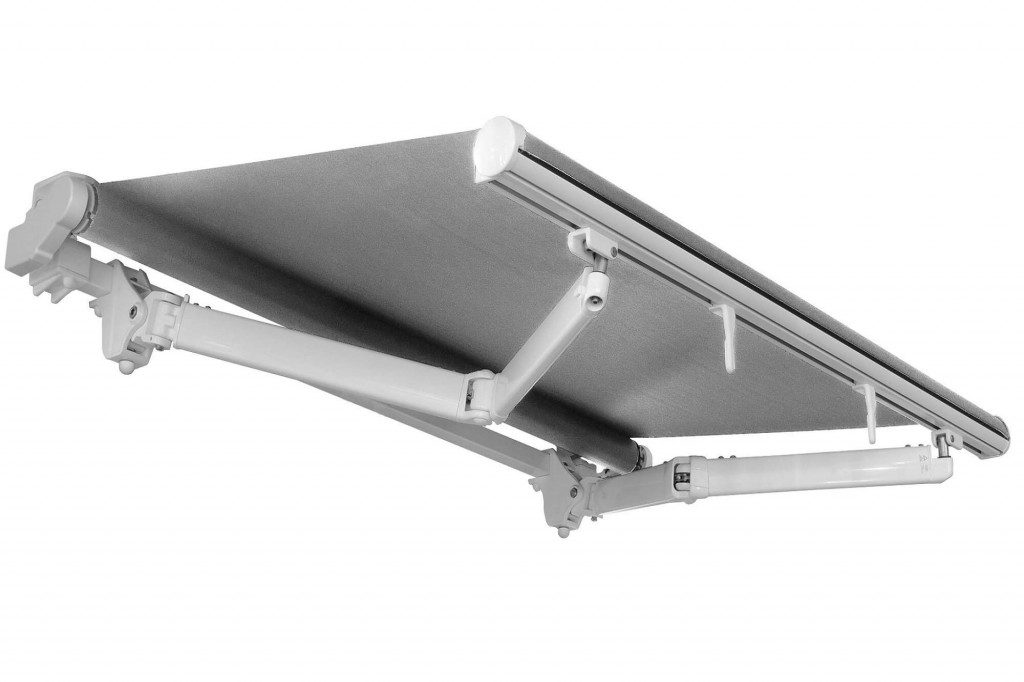

Patio retractable awnings have another vital component: a frame with a roller tube. When partially or fully retracted, the awning fabric wraps around the roller tube and unwraps when extended. The frame and roller tube are attached to the building surface (wall, beam, roof, rafter, soffit/eave/overhang) using special mounting brackets, which we’ll discuss in the following sections.

Types of cassettes

Depending on the model and cassette, retractable awnings can be classified as open, semi-cassette or full cassette. Open retractable awnings leave the fabric wrapped up around the roller tube and exposed to the elements if no hood/cover is used. If a rigid, aluminum hood/cover is used some coverage occurs.

Semi-cassette awnings provide partial coverage for the material and other awning components, while the full-cassette covers all parts completely and offers complete protection.

What are the types of support arms?

Retractable awning mechanisms can vary in support arms used for extension and retraction. The support arm consists of two elements (sections) and a connecting elbow joint that performs movements similar to flexion and extension.

Typically, we divide the components into articulated spring-loaded (folding mechanical) or telescopic (hydraulic). Both types of structural support have some similarities and differences that we need to consider.

Similarities between articulated spring-loaded and telescopic arms

Let’s begin with the similarities between the two types of awning support arms. In both cases, you can extend or retract the retractable awning to any movement point up until its full projection, so you are not restricted by the mechanism.

Another similarity is that you can adjust the canopy’s pitch (angle) so rainwater (light rain only) runs off and doesn’t pool on top of the fabric with both types of support arms.

Differences between articulated spring-loaded and telescopic arms

The main difference between articulated spring-loaded and telescopic arms is their working mechanism. Spring-loaded arms work by extending one section, which “unlocks” the next section’s spring, so it also begins to unfold. For awnings with telescopic arms, vendors use gas pistons that move gas across the arms to extend and retract them.

Generally speaking, articulated arms are more commonly used and preferred than telescopic ones because of their longer lifespan and lower cost. With telescopic arms, you may need to fix potential leaks in the gas piston, while with articulated arms, you don’t have to worry about such maintenance.

What is a front (header) bar?

The front bar also referred to as the header bar, is a long aluminum extrusion attached to the front of the canopy cover via the arms. Its function is to keep the fabric taut when partially or fully extended, and it’s connected to the awning’s support arms.

The front bar increases wind resistance by keeping the material tight and helps keep the awning sturdy in the low wind.

What is the drivetrain in a retractable awning?

The drivetrain in retractable awnings with articulated spring-loaded arms can be a cable, a chain or a belt. They apply tension on the springs when they are fully stretched (when you retract the awning fully). While some vendors offer retractable awning models with cables and belts, I recommend choosing high-quality non-rusting stainless steel chains as they will last the longest.

What are mounting brackets made of?

High-quality mounting brackets are essential for outdoor retractable awnings since they are constantly exposed to the elements.

A few different mounting brackets exist, depending on the installation surface for which they are intended :

- Wall, beam or fascia brackets

- Soffit/eave/overhang brackets

- Roof brackets

- Rafter brackets

The production materials of extendable awnings mounting brackets are of essential importance for safety reasons and the longevity of the construction of a retractable awning.

Some vendors offer plastic brackets, which are not reliable and recommended. I recommend purchasing only non-corroding and non-rusting materials such as powder-coated stainless steel or aluminum for essential components like brackets, nuts and bolts, which need to keep the retractable awning in place.

What are a retractable awning handle/crank and a motor?

Home retractable awnings can be separated into manual (mechanical awnings) and electric (motorized retractable awnings). Based on the extension mechanism, you can retract and extend the canopy manually, using a detachable hand crank or electrically, using a wall switch, remote control or a mobile app.

Detachable hand cranks

Detachable hand cranks are long metal rods that you can use to extend and retract your manually operated awning and with some retractable awnings adjust the pitch/angle of the awning. The rod has two ends – one is a hook that attaches at either end of the retractable awning, and the other is a handle that you turn to create motion and rotate the roller tube.

Manual operation is generally suitable for smaller-sized awnings that are not so heavy and difficult to operate. They do not require electricity and come at a lesser cost than motorized versions.

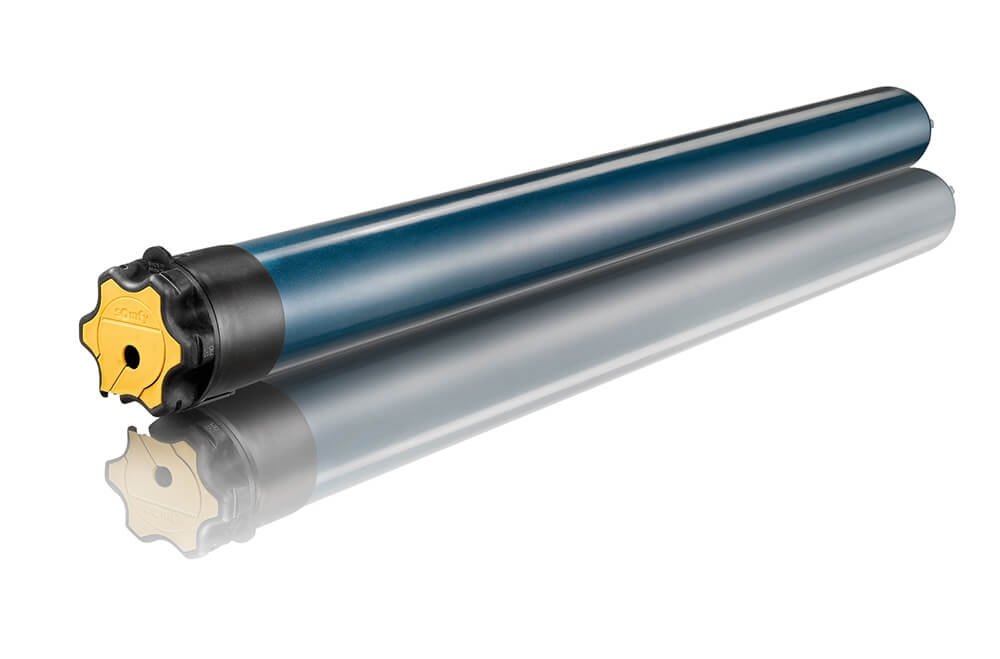

Electric motors

Electric motors are used to extend and retract motorized awnings. You can operate them via remote control, a wall switch, home automation or a mobile application, and they require 110v or 220v electricity.

Motorized models normally are available with an optional manual override in case of electricity – a power outage. They are suitable for larger-sized awnings with heavy canopies, and the best motors are Simu and Somfy.